How to Calculate the Polyurethane Foam for Insulation & Slab Lifting

Published on Sep 19, 2024

How to Calculate the Polyurethane Foam Needed for Insulation and Slab Lifting Jobs

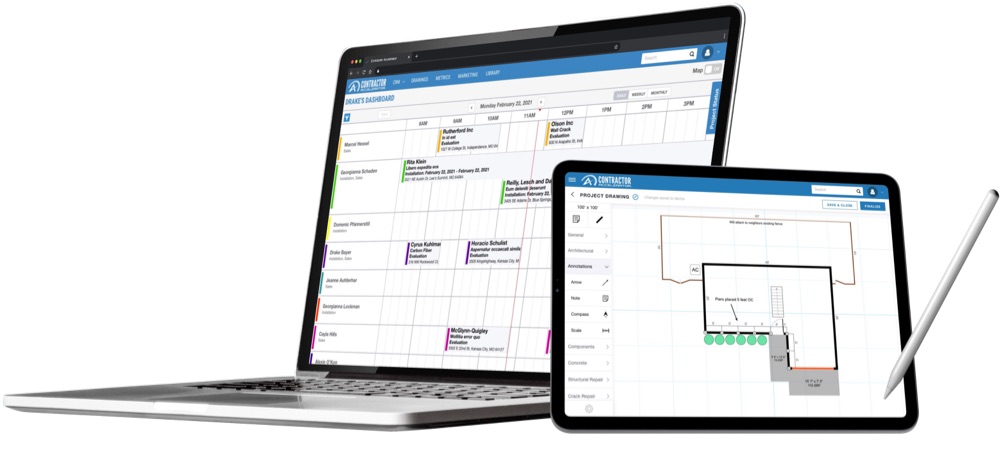

If you're a spray foam contractor working on insulation or slab lifting, knowing how to calculate the amount of polyurethane foam needed is key to pricing your services and ensuring you have enough material on hand. Fortunately, software like Contractor Accelerator can automatically handle these calculations for you, saving you time and ensuring accuracy. With a few inputs, the software can instantly determine the amount of foam required, factoring in area, thickness, density, and overage.

However, if you prefer to do it manually, you can still calculate the foam needed for both types of jobs using the formulas below and set yourself up for success.

Polyurethane Foam for Insulation

When you’re insulating walls, ceilings, or attics, you typically use a board foot calculation. A board foot is a unit of measurement equal to 1 square foot of surface area sprayed with 1 inch of foam thickness. To determine how much foam you’ll need:

- Measure the area: Determine the square footage of the surface that needs insulation. For example, if you're insulating a wall that’s 10 feet by 8 feet, that gives you 80 square feet.

- Choose the thickness: Decide how thick the foam needs to be for the project. Standard insulation might require a 2-inch thick layer.

- Calculate the board feet: Multiply the square footage by the thickness in inches to get board feet. In our example, 80 square feet multiplied by 2 inches gives you 160 board feet.

The price of spray foam is typically quoted per board foot, so once you know the board footage required, you can multiply that by your cost per board foot to get the total price for the job.

Polyurethane Foam for Slab Lifting

Slab lifting, also known as polyjacking, has been revolutionized by polyurethane foam. It’s a more efficient and longer-lasting alternative to traditional mudjacking, where mud is pumped under concrete to level it. Here’s how to calculate the foam needed for slab lifting:

- Measure the area of the slab: Take the length and width of the area you need to lift, in feet. Let’s say the slab is 4 feet by 3 feet.

- Estimate the lift: Determine the height in inches of how much the slab needs to be raised. For example, if the slab has sunk 2 inches, that’s your height.

- Calculate the volume in cubic inches: To calculate this, use the number 1728 as it is the volume of 12 inch cube and follow the formula below:

- (Length in Feet * 12) * (Width in Feet * 12) * Height in Inches / 1728 ) = Volumn in cubic inches

- (Volume in cubic inches * Density) * (1 + Overage %) = Pounds of Sprayfoam needed

- Pounds of Sprayfoam needed * Price per pound = Price for project

- In our example, you’d calculate:

- (4∗12)∗(3∗12) ∗ 2 / 1728 = 2 cubic feet (or 3456 cubic inches)

- Multiply by the foam’s density: The density of the polyurethane foam will vary, but you should know the specific density for the foam you're using. Multiply the volume in cubic inches by the density to get the foam weight needed in pounds.

- Add an overage percentage: To ensure you have enough foam, add a standard overage percentage. Let’s say you allow for a 10% overage. Multiply the weight of the foam by 1.1 (for 10%) to get the total pounds of foam required.

- Calculate the cost: Multiply the total pounds of foam by your cost per pound to get the total material cost for the project.

Example Slab Lifting Calculation:

- Slab dimensions: 4 feet by 3 feet

- Sinking depth: 2 inches

- Foam density: 2 pounds per cubic foot

- Overage percentage: 10%

- Price per pound: $5

Step 1: Volume in cubic inches:

(4∗12)∗(3∗12)∗2/1728 = 2 cubic feet

Step 2: Pounds of foam:

2 cubic feet ∗ 2 pounds = 4 pounds of foam

Step 3: Add overage:

4 pounds ∗1.1 = 4. 4 pounds of foam

Step 4: Price of foam:

4.4 pounds * $5 = $22

The total material cost for this job would be $22.

Wrapping It Up

Whether you’re working on insulating a home or leveling a sunken slab, having accurate calculations will help you confidently price your services and ensure you have enough polyurethane foam on hand. For insulation jobs, board feet are the key, while slab lifting requires a bit more math to account for foam volume and density. Both services offer excellent opportunities to showcase the benefits of polyurethane foam to your customers, ensuring they get the long-lasting, efficient results they’re looking for.

By understanding these calculations, you can better estimate project costs, avoid over or under-ordering materials, and ensure smooth, efficient service for your customers.